Accurate Printer PCB Board Seat with Intelligent Adjustment and 4mil Minimum Gap

-

Highlight

Intelligent Adjustment PCB Board Seat

,Accurate PCB Board Seat

,4mil Minimum Gap PCB Board Seat

-

Applicable ProductsCar Seat Control

-

Application AreaNew Energy

-

Plate Thickness Tolerance (t ≥ 1.0mm)±10%

-

Plate Thickness Tolerance (t<1.0mm)±0.1mm

-

Minimum Line Width4mil(0.1mm)

-

Minimum Gap4mil(0.1mm)

-

Finished Product Inner Copper Thickness35um

-

Drilling Hole Diameter (machine Drill)0.25-6.3mm

-

Place of OriginChina

-

Model NumberAutomotive seat PCB board

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom packaging

Accurate Printer PCB Board Seat with Intelligent Adjustment and 4mil Minimum Gap

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

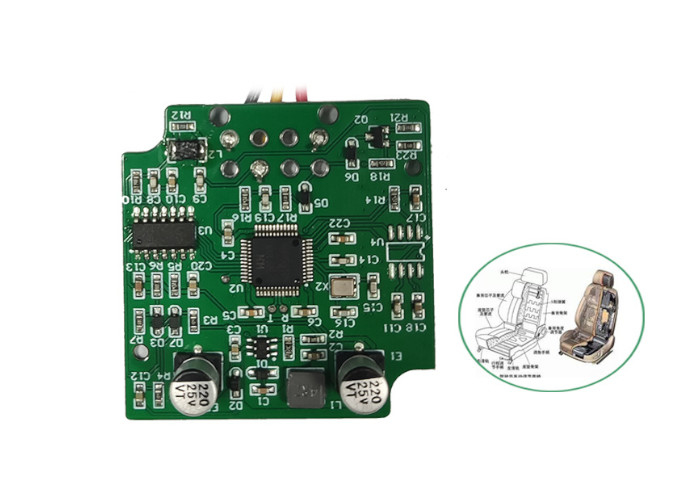

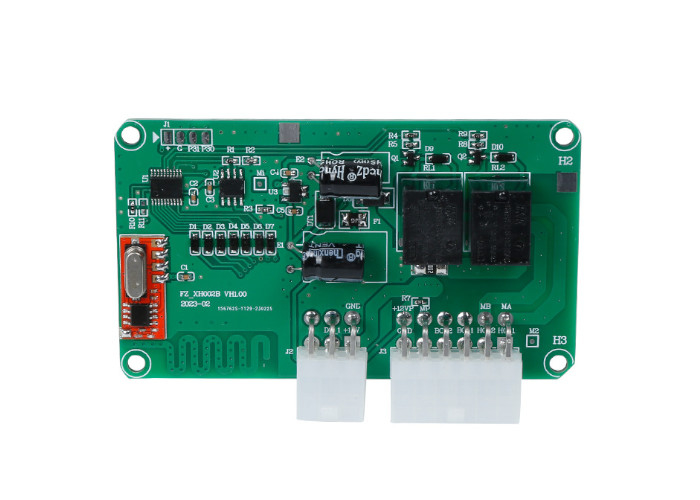

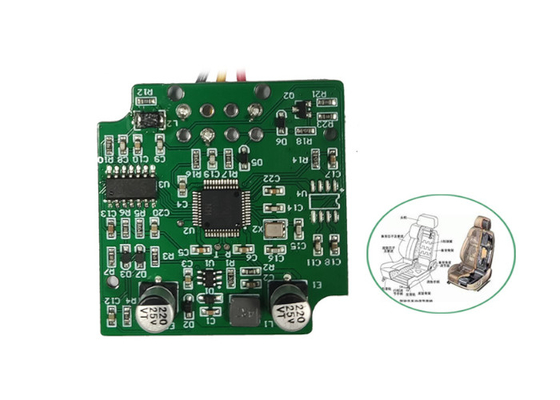

The automotive seat adjustment PCBA solution board is a high-quality electronic product meticulously designed specifically for seat control in new energy vehicles. This product ingeniously integrates advanced control technology and intelligent elements. It is capable of meeting the personalized needs of different drivers and passengers, providing them with a more comfortable and convenient driving and riding experience. With its precise control and intelligent functions, it not only enhances the overall quality of the vehicle but also reflects the pursuit of innovation and excellence in the automotive industry.

Technical Parameter:

| Project | Detailed parameters | Processing capability |

|---|---|---|

| Number of layers | Floors 1-14 | Layer number refers to the number of layers in the design document, which can produce 1-16 layers of through-hole plates |

| Printing ink | Sun series | White oil: Sun 2000 series, green oil: Sun 07 series |

| Board type | CEM-1/FR4, Aluminum substrate | CEM-1 sheet/FR-4 sheet/aluminum based sheet |

| Maximum size | 650x520mm/640x480mm | The maximum size for both sides is 650x520mm, and the maximum size for four or six layers is 640x480mm |

| Accuracy of external dimensions | ±0.15mm | CNC shape tolerance ± 0.15mm, V-cut board shape tolerance+1.5mm |

| Plate thickness range | 0.4--2.0mm | At present, the production plate thickness is 0.4/0.6/0.8/1.0/1.2/1.6/2.0mm |

| Plate thickness tolerance (t ≥ 1.0mm) | ±10% | Please note that due to production process reasons (such as copper deposition, solder mask, and pad spraying, which may increase plate thickness), positive tolerances are generally used |

| Plate thickness tolerance (t<1.0mm) | ±0.1mm | Please note that due to production process reasons (such as copper deposition, solder mask, and pad spraying, which may increase plate thickness), positive tolerances are generally used |

| Minimum line width | 4mil(0.1mm) | At present, it can accommodate a line width of 4mil, and the line width should be as large as possible to be greater than 4mil |

![]()

Applicable scenarios:

Primarily utilized in the control system of new energy vehicle seats, the automatic adjustment function of the seats is achieved through highly integrated and precisely designed PCBA solution boards. This enables the seats to be adjusted with ease and precision, meeting the diverse needs of drivers and passengers. The advanced technology and reliable performance of these PCBA solution boards contribute to enhancing the overall comfort and functionality of new energy vehicles.

Product Function:

Control Function: It supports the electric adjustment of car seats. This includes, but is not limited to, forward and backward movement, up and down lifting, and backrest tilting. By doing so, it enhances driving and riding comfort. The precise control and diverse adjustment options allow users to customize their seating positions according to their individual preferences and needs.

Intelligence: It may integrate intelligent components such as sensors and controllers. Through this integration, it can achieve automatic seat adjustment and memory functions. This enables the seat to adapt to the needs of different drivers and passengers. The intelligent features not only add convenience but also enhance the overall user experience, making driving and riding more enjoyable and comfortable.

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

Automotive seat adjustment PCBA circuit board is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()