Precise MEMS Differential Pressure Sensor for Airflow Monitoring

-

Highlight

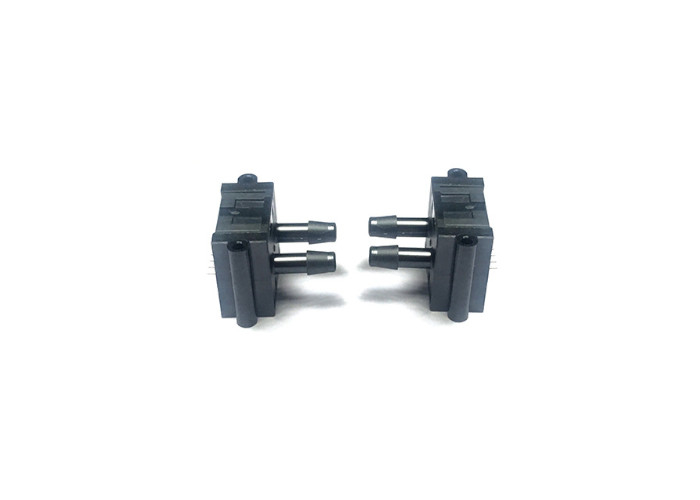

Airflow Monitoring Differential Pressure Sensor

,Precise MEMS Differential Pressure Sensor

,Airflow Monitoring MEMS Differential Pressure Sensor

-

Detectable Gas TypesAir

-

Accuracy-500~+500Pa(±2in.H2O)

-

Type Of OutputDigital Output

-

Working Temperature80℃

-

Supply Voltage3.6V

-

Power Supply Current6mA

-

Application AreaNew Energy

-

Sensor TypeDifferential Pressure Sensor

-

Applicable ProductsFresh Air System

-

Place of OriginJapan

-

Model NumberD6F

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom packaging

Precise MEMS Differential Pressure Sensor for Airflow Monitoring

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

This product is a high-precision MEMS differential pressure sensor designed specifically for air flow monitoring, integrating advanced micro mechanical system technology to ensure accurate measurement of small pressure differences. Widely applicable in fields such as medical equipment, environmental monitoring, and industrial automation that require precise airflow control. Sensors have the characteristics of fast response, high stability, low power consumption, and high protection level, which can be easily integrated into various systems to help users accurately control airflow data, improve work efficiency and product quality.

Technical Parameter:

| Model | D6F-PHO025AD1 | D6F-PHO025AD2 | D6F-PH0025AMD2 | D6F-PHO505AD3 | D6F-PHO505AD4 | D6F-PHO505AMD4 |

| Flow range | 0~250Pa | ±50Pa | ||||

| Applicable fluids | Air | |||||

| Joint shape | Sleeve joint Maximum outer diameter ∅ 4.9mm, minimum outer diameter ∅ 4.0mm |

Duplex joint | Sleeve joint Maximum outer diameter ∅ 4.9mm, minimum outer diameter ∅ 4.0mm |

Duplex joint | ||

| Terminal specifications | Wire terminal | 4-terminal connector | Wire terminal | 4-terminal connector | ||

| Supply voltage | DC2.3-3.6V | |||||

| Current consumption | No load, Vcc=DC3.3V, GND=DC0V, below 6mA at 25 ℃ | |||||

| Resolving power | 12bit | |||||

| Zero point accuracy | ±0.2Pa | |||||

| Full scale accuracy | ±3%R.D. | |||||

| Temperature characteristics (full-scale) | Within ± 0.5% R.D. every 10 ℃ | |||||

| Response speed | Typ.33ms, Max.50ms (12 bits) Conversion time Typ.6ms (12 bits) |

|||||

| Sensors pass through flow | Below 63mL/min | Below 23mL/min | ||||

| Communication mode | 12C | |||||

| Shell material | PPS | |||||

| Protection structure | IEC IP40 (excluding piping department) | |||||

| Voltage resistance | 10kPa | |||||

| Operating temperature range | -20~+80℃ | |||||

| Operating humidity range | 35~85%RH | |||||

| Save temperature range | -40~+80℃ | |||||

| Save humidity range | 35~85%RH | |||||

| Insulation resistance | Above 20M Ω (DC500V insulation resistance) between the outer wall of the sensor and the wire terminal | |||||

| Voltage resistance | AC500V 50/60Hz 1 minute (leakage current below 1mA) between the outer wall of the sensor and the wire terminal | |||||

| weight | 5.0g | 5.0g | 5.4g | 5.0g | 5.4g | 5.0g |

Applicable scenarios:

Medical equipment: used in ventilators, oxygen concentrators and other devices to accurately monitor gas flow and ensure patient safety.

Environmental monitoring: monitoring indoor air quality, such as the application of fresh air systems and air purifiers, to improve the quality of living environment.

Industrial automation: Monitoring gas flow in the production line, controlling the production process, improving production efficiency and product quality.

Aerospace: In the field of aerospace, it is used for high-precision airflow monitoring such as engine testing and cabin environment control.

Product Function:

Accurate measurement: Utilizing MEMS technology to achieve precise measurement of small pressure differences.

High stability: Excellent long-term stability ensures data reliability.

Quick response: Quick response design, suitable for dynamically changing environments.

Easy to integrate: Standard interface design for easy integration with various systems.

Low power consumption: Low power design reduces operating costs.

High protection: High protection level, suitable for various harsh environments.

Data output: Provides multiple output signals to meet the connection needs of different devices.

Widely applicable: Suitable for multiple fields such as medical equipment, environmental monitoring, industrial automation, etc.

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

Air flow sensor, micro pressure differential sensor is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()