-

Highlight

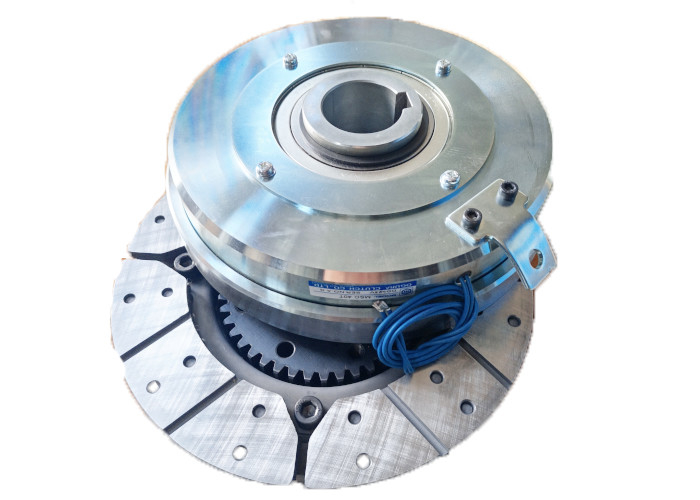

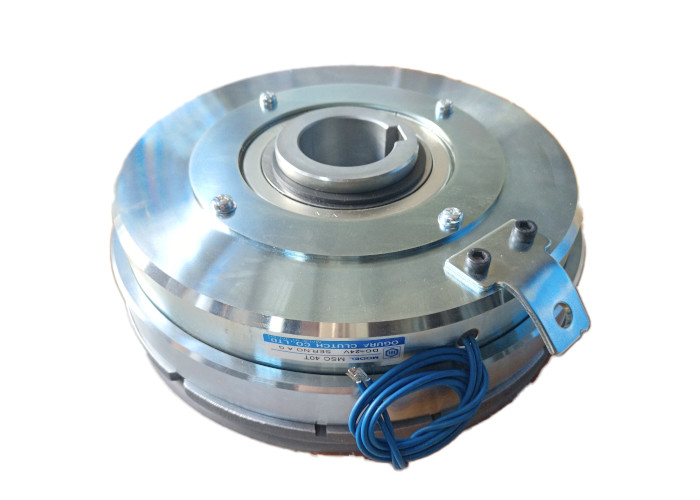

single board electromagnetic clutch/brake

,OEM Printer Clutch

-

Heat Dissipation CapabilityStrong

-

TypeSpline Type Drive

-

Power ModelOTPF/H45/H70/H130

-

Rectification MethodSingle-phase Full Wave

-

Frequency50/60Hz

-

AC Input Voltage100V/200V

-

DC Output24V

-

Reaction CapacityExcellent

-

Place of OriginJapan

-

Model NumberMS series

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom packaging

OEM Printer Clutch MS Series Dry Single Board Electromagnetic Clutch/brake

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

The Electromagnetic Clutch&Brake MS series products are widely used in various mechanical equipment due to their wide torque range, excellent design features, convenient installation methods, and diverse combination options. By precise control of torque, efficient heat dissipation, automatic clearance adjustment and other functions, the operating efficiency and reliability of the equipment have been improved, meeting the industrial demand for high-performance clutches and brakes.

Technical Parameter:

MSC - T Dry Single - board Electromagnetic Clutch [Bearing Type]

Type 1.2, Type 2.5, Type 5, Type 10.

Torque: 12 - 100 N·m.

| Model | MSC | 1.2T | 2.5T | 5T | 10T | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 12 | 25 | 50 | 100 | |

| Inertance | J×10-4[kg·m2] | Rotor end | 3.3 | 8.5 | 22 | 73 |

| Armature end | 5.5 | 13.8 | 39 | 86 | ||

| Bore diameter | dH7 | 15 | 20 | 25 | 30 | |

| Keyway | bE9×t+0.15 | 5×17 | 5×22 | 7×28 | 7×33 | |

| Circumferential direction | A | 90 | 110 | 140 | 175 | |

| CH7 | 32 | 42 | 52 | 62 | ||

| D | 85.1 | 103.5 | 133 | 165 | ||

| E | 52 | 65 | 80 | 95 | ||

| F | 5 | 6 | 6 | 10 | ||

| G | 14 | 16 | 16 | 24 | ||

| H | 4.5 | 5.5 | 5.5 | 8.5 | ||

| J | 40 | 50 | 62 | 75 | ||

| K1 | 3-4.5 | 3-5.5 | 3-6.5 | 3-8.5 | ||

| K2 | 3-M4 | 3-M5 | 3-M6 | 3-M8 | ||

| Shaft direction | L | 50 | 59 | 69 | 85 | |

| M | 25 | 32 | 35 | 48 | ||

| N | 19 | 19 | 16 | 17 | ||

| O | 6 | 8 | 18 | 20 | ||

| P | 11 | 13 | 21 | 23.5 | ||

| Q | 1.4 | 3 | 2 | 3.1 | ||

| R | 1.6 | 2 | 2 | 2.9 | ||

| S | 0.3 | 0.3 | 0.3 | 0.4 | ||

| Bearing applicable to armature | 6002ZZ | 6004ZZ | 6205ZZ | 6206ZZ | ||

| Mass [kg] | 1.5 | 2.3 | 4.2 | 8.4 | ||

![]()

MSC - T Dry Single - board Electromagnetic Clutch [Bearing Type].

Type 20, Type 40, Type 70, Type 100.

Torque: 200 - 1000 N·m.

| Model | MSC | 20T | 40T | 70T | 100T | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 200 | 400 | 700 | 1000 | |

| Inertance | J×10-4[kg·m2] | Rotor end | 221 | 550 | 1030 | 2830 |

| Armature end | 240 | 550 | 1240 | 2630 | ||

| Bore diameter | dH7 | 40 | 50 | 60 | 70 | |

| Keyway | bE9×t+0.15 | 10×43.5 | 15×55 | 15×65 | 18×76 | |

| Circumferential direction | A | 220 | 260 | 315 | 380 | |

| CH7 | 80 | 90 | 110 | 125 | ||

| D | 207.2 | 243 | 293 | 360 | ||

| E | 120 | 140 | 170 | 210 | ||

| F | 10 | 12 | 13 | 13 | ||

| G | 24 | 28 | 30 | 30 | ||

| H | 8.5 | 10.5 | 13 | 13 | ||

| J | 94 | 110 | 130 | 150 | ||

| K1 | 3-8.5 | 4-10.5 | 4-13 | 4-13 | ||

| K2 | 3-M8 | 4-M10 | 4-M12 | 4-M12 | ||

| Shaft direction | L | 96 | 110 | 123 | 138 | |

| M | 53 | 65 | 70 | 80 | ||

| N | 20 | 20 | 25 | 28 | ||

| O | 23 | 25 | 28 | 30 | ||

| P | 27 | 29 | 33 | 35 | ||

| Q | 3.1 | 6.8 | 2.8 | 14.8 | ||

| R | 2.9 | 3.2 | 3.2 | 3.2 | ||

| S | 0.5 | 0.7 | 0.7 | 0.8 | ||

| Bearing applicable to armature | 6208ZZ | 6210ZZ | 6212ZZ | 6214ZZ | ||

| Mass [kg] | 14 | 22 | 35 | 52 | ||

![]()

MSB Dry Single - board Electromagnetic Brake.

Type 1.2, Type 2.5, Type 5.

Torque: 12 - 50 N·m.

| Model | MSB | 1.2 | 2.5 | 5 | |

|---|---|---|---|---|---|

| Static friction torque | [N·m] | 12 | 25 | 50 | |

| Inertance | J×10-4[kg·m2] | 5.5 | 13.8 | 39 | |

| Bore diameter | dH7 | 15 | 20 | 25 | |

| Keyway | bE9×t+0.15 | 5×17 | 5×22 | 7×28 | |

| Circumferential direction | A | 90 | 110 | 140 | |

| B | 28 | 42 | 50 | ||

| DH8 | 46 | 54 | 74 | ||

| E | 85 | 103 | 133 | ||

| Fh8 | 115 | 135 | 170 | ||

| G | 100 | 120 | 150 | ||

| H | 4-4.5 | 4-4.5 | 4-4.5 | ||

| Shaft direction | L | 50 | 57.3 | 67 | |

| M | 21 | 21 | 20 | ||

| N | 28 | 35 | 45 | ||

| P | 1 | 1.3 | 2 | ||

| Q | 2 | 2.4 | 2.4 | ||

| R | 31 | 36 | 39 | ||

| S | 0.3 | 0.3 | 0.3 | ||

| Mass [kg] | 1.2 | 2.2 | 4 | ||

![]()

MSB dry single - plate electromagnetic brake

Type 10, Type 20, Type 40, Type 70, Type 100.

Torque: 100 - 1000 N·m.

| Model | MSB | 10 | 20 | 40 | 70 | 100 | |

|---|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 100 | 200 | 400 | 700 | 1000 | |

| Inertance | J×10-4[kg·m2] | 86 | 250 | 580 | 1260 | 2730 | |

| Bore diameter | dH7 | 30 | 40 | 50 | 60 | 70 | |

| Keyway | bE9×t+0.15 | 7×33 | 10×43.5 | 15×55 | 15×65 | 18×76 | |

| Circumferential direction | A | 175 | 220 | 260 | 315 | 380 | |

| B | 50 | 72 | - | 128 | - | ||

| DH8 | 72 | 80 | 110 | 145 | 190 | ||

| G | 85 | 98 | 132 | 170 | 218 | ||

| H | 6-6.5 | 6-8.5 | 6-10.5 | 6-12.5 | 8-12.5 | ||

| Shaft direction | L | 81.1 | 90.8 | 100 | 114.5 | 117 | |

| M | 30 | 20 | 24 | 24 | 17 | ||

| N | 50 | 70 | 76 | 90 | 100 | ||

| P | 1.1 | 0.8 | 0 | 0.5 | 0 | ||

| Q | 3.3 | 2.9 | 3.7 | 3.7 | 3.7 | ||

| R | 48 | 52 | 56 | 61 | 59 | ||

| S | 0.4 | 0.5 | 0.7 | 0.7 | 0.8 | ||

| Mass [kg] | 8 | 14 | 21 | 34 | 51 | ||

![]()

MSCP Dry Single - board Electromagnetic Clutch Device [Alignment Shaft Type].

Type 1.2, Type 2.5, Type 5, Type 10.

Torque: 12 - 100 N·m.

| Model | MSCP | 1.2 | 2.5 | 5 | 10 | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 12 | 25 | 50 | 100 | |

| inertance | J×10-4(kg·m2) | input shaft | 3.5 | 9.3 | 24 | 75 |

| output shaft | 6.0 | 14.3 | 40 | 88 | ||

| bore diameter | dh7 | 15 | 20 | 25 | 30 | |

| key slot | bh8×t-0.02 | 5×17 | 5×22 | 7×28 | 7×33 | |

| circumferential direction | A | 126 | 157 | 197 | 235 | |

| B | 136 | 156 | 190 | 230 | ||

| C | 110 | 130 | 160 | 200 | ||

| D | 63 | 80 | 102 | 120 | ||

| E | 10 | 12 | 15 | 15 | ||

| F | 98 | 112 | 130 | 150 | ||

| G | 71 | 71 | 71 | 71 | ||

| H | 8.5 | 8.5 | 11 | 11 | ||

| shaft direction | L | 231 | 264 | 303 | 350 | |

| M | 168 | 185 | 212 | 246 | ||

| N | 142 | 157 | 180 | 214 | ||

| P | 34 | 42 | 49 | 58 | ||

| Q | 29 | 37 | 42 | 46 | ||

| R | 27 | 36 | 45 | 54 | ||

| S | 22 | 31 | 40 | 49 | ||

| Y×profundity | M5×10 | M6×12 | M8×16 | M8×16 | ||

| Mass [kg] | 3.5 | 5.8 | 10.5 | 19.0 | ||

![]()

MSCP dry single-plate electromagnetic clutch device [alignment shaft type]

Type 20, Type 40, Type 70, Type 100.

Torque: 200 - 1000N·m.

| Model | MSCP | 20 | 40 | 70[special] | 100[special] | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 200 | 400 | 700 | 1000 | |

| inertance | J×10-4(kg·m2) | input shaft | 240 | 580 | 1100 | 3000 |

| output shaft | 260 | 590 | 1280 | 2900 | ||

| bore diameter | dh7 | 40 | 50 | 60 | 70 | |

| key slot | bh8×t-0.02 | 10×43.5 | 15×55 | 15×65 | 18×76 | |

| circumferential direction | A | 295 | 350 | 395 | 452 | |

| B | 280 | 340 | 400 | 460 | ||

| C | 240 | 290 | 340 | 390 | ||

| D | 150 | 180 | 200 | 227 | ||

| E | 18 | 25 | 30 | 30 | ||

| F | 180 | 205 | 231 | 261 | ||

| G | 71 | 71 | 71 | 71 | ||

| H | 13 | 17 | 21 | 21 | ||

| shaft direction | L | 427 | 508 | 640 | 710 | |

| M | 288 | 334 | 408 | 468 | ||

| N | 246 | 282 | 320 | 400 | ||

| P | 76 | 94 | 116 | 121 | ||

| Q | 63 | 80 | 116 | 121 | ||

| R | 72 | 90 | 105 | 110 | ||

| S | 67 | 80 | 90 | 90 | ||

| Y×profundity | M10×20 | M10×20 | M12×25 | M12×25 | ||

| Mass [kg] | 32.5 | 55 | 115 | 150 | ||

![]()

MSU dry single-plate electromagnetic clutch/brake assembly [alignment shaft type].

Type 1.2, Type 2.5, Type 5, Type 10.

Torque: 12 - 100N·m.

| Model | MSU | 1.2 | 2.5 | 5 | 10 | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 12 | 25 | 50 | 100 | |

| inertance | J×10-4(kg·m2) | input shaft | 3.5 | 9.3 | 24 | 75 |

| output shaft | 11 | 27.5 | 80 | 173 | ||

| bore diameter | dh7 | 15 | 20 | 25 | 30 | |

| key slot | bh8×t-0.02 | 5×17 | 5×22 | 7×28 | 7×33 | |

| circumferential direction | A | 126 | 157 | 197 | 235 | |

| B | 136 | 156 | 190 | 230 | ||

| C | 110 | 130 | 160 | 200 | ||

| D | 63 | 80 | 102 | 120 | ||

| E | 10 | 12 | 15 | 15 | ||

| F | 98 | 112 | 130 | 150 | ||

| G | 71 | 71 | 71 | 71 | ||

| H | 8.5 | 8.5 | 11 | 11 | ||

| shaft direction | L | 244 | 277 | 320 | 373 | |

| M | 176 | 191 | 220 | 255 | ||

| N | 150 | 165 | 190 | 225 | ||

| P | 34 | 43 | 50 | 59 | ||

| R | 27 | 36 | 45 | 54 | ||

| S | 22 | 31 | 40 | 49 | ||

| Y×profundity | M5×10 | M6×12 | M8×16 | M8×16 | ||

| Mass [kg] | 5.0 | 8.0 | 15.0 | 25.5 | ||

![]()

MSU dry single-plate electromagnetic clutch/brake assembly [alignment shaft type].

Type 20, Type 40, Type 70, Type 100.

Torque: 200 - 1000N·m.

| Model | MSU | 20 | 40 | 70[special] | 100[special] | |

|---|---|---|---|---|---|---|

| Static friction torque | [N·m] | 200 | 400 | 700 | 1000 | |

| inertance | J×10-4(kg·m2) | input shaft | 240 | 580 | 1100 | 3000 |

| output shaft | 480 | 1080 | 2450 | 5300 | ||

| bore diameter | dh7 | 40 | 50 | 60 | 70 | |

| key slot | bh8×t-0.02 | 10×43.5 | 15×55 | 15×65 | 18×76 | |

| circumferential direction | A | 295 | 350 | 395 | 452 | |

| B | 280 | 340 | 400 | 460 | ||

| C | 240 | 290 | 340 | 390 | ||

| D | 150 | 180 | 200 | 227 | ||

| E | 18 | 25 | 30 | 30 | ||

| F | 180 | 205 | 231 | 261 | ||

| G | 71 | 71 | 71 | 71 | ||

| H | 13 | 17 | 21 | 21 | ||

| shaft direction | L | 454 | 540 | 640 | 710 | |

| M | 300 | 350 | 408 | 468 | ||

| N | 260 | 300 | 320 | 400 | ||

| P | 77 | 95 | 116 | 121 | ||

| R | 72 | 90 | 105 | 110 | ||

| S | 67 | 80 | 90 | 90 | ||

| Y×profundity | M10×20 | M10×20 | M12×25 | M12×25 | ||

| Mass [kg] | 44.0 | 71.5 | 145 | 190 | ||

![]()

Performance table [operating characteristics].

MS type, Type 1.2, Type 2.5, Type 5, Type 10, Type 20, Type 40, Type 70, Type 100.

| model | Static friction torque [N · m] | Coil (20 ℃) | Magnet attraction time (S) | Torque rise time (S) | Release time of armature (S) | Allowable number of rotations (r/min) | |||

| Voltage (DC-V) | Current (A) | Resistance (Ω) | Power capacity (W) | ||||||

| MSC 1.2T | 12 | 24 | 0.69 | 35 | 17 | 0.040 | 0.050 | 0.040 | 5500 |

| MSB 1.2 | |||||||||

| MSC 2.5T | 25 | 24 | 1.04 | 23 | 25 | 0.050 | 0.070 | 0.060 | 5000 |

| MSB 2.5 | |||||||||

| MSC 5T | 25 | 24 | 1.26 | 19 | 30 | 0.060 | 0.100 | 0.060 | 4000 |

| MSB 5 | |||||||||

| MSC 10T | 50 | 24 | 1.46 | 16.4 | 35 | 0.080 | 0.140 | 0.090 | 3600 |

| MSB 10 | |||||||||

| MSC 20T | 100 | 24 | 2.09 | 11.5 | 50 | 0.100 | 0.180 | 0.110 | 2600 |

| MSB 20 | |||||||||

| MSC 40T | 400 | 24 | 2.70 | 8.9 | 65 | 0.140 | 0.230 | 0.140 | 2400 |

| MSB 40 | |||||||||

| MSC 7OT | 700 | 24 | 3.75 | 6.4 | 90 | 0.170 | 0.300 | 0.160 | 2000 |

| MSB 70 | |||||||||

| MSC 100T | 1000 | 24 | 4.14 | 5.8 | 100 | 0.220 | 0.380 | 0.180 | 1800 |

| MSB 100 | |||||||||

Performance table [workload].

MS type, Type 1.2, Type 2.5, Type 5, Type 10, Type 20, Type 40, Type 70, Type 100.

|

MODEL MSC-T,MSB |

Maximum total workload [J]. |

| 1.2 | 18×107 |

| 2.5 | 27×107 |

| 5 | 56×107 |

| 10 | 83×107 |

| 20 | 160×107 |

| 40 | 230×107 |

| 70 | 370×107 |

| 100 | 520×107 |

Applicable scenarios:

Wide applicability: Suitable for various mechanical equipment, including but not limited to industrial automation, robots, machine tools, packaging machinery, textile machinery, etc.

Combination flexibility: Individual clutch and brake products, clutch devices, clutch and brake combinations, and various machine types can be assembled to meet the needs of different scenarios.

Improve efficiency: By quickly generating and releasing torque, precise actions can be achieved, improving equipment operating efficiency and accuracy.

Product Function:

Torque control: capable of quickly responding and accurately controlling the transmission and disconnection of torque, ensuring the stability and reliability of equipment operation.

Heat dissipation and durability: With excellent heat dissipation capabilities, it ensures temperature control during long-term operation and improves product durability.

Automatic gap adjustment: Equipped with an automatic gap adjustment device, there is no need to manually adjust the gasket, reducing maintenance costs and time.

Rapid response: The optimized electromagnetic system is designed to enable the clutch and brake to respond quickly, improving production efficiency.

Protection mechanism: Comes with protective elements and other accessories to provide additional security and extend the product's lifespan.

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

MS series dry single board electromagnetic clutch/brake is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()