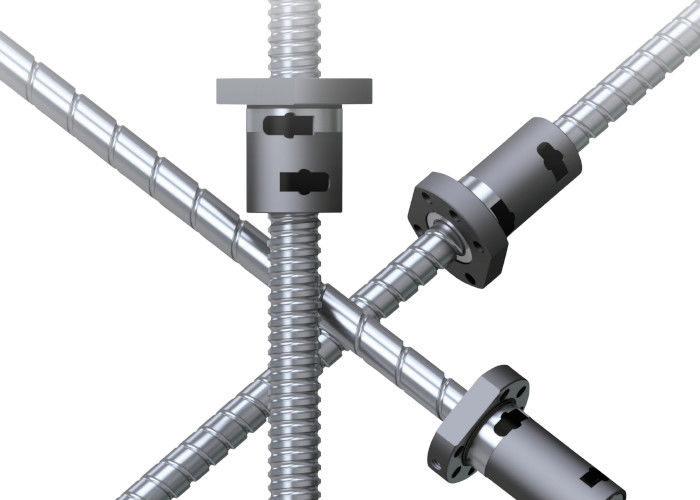

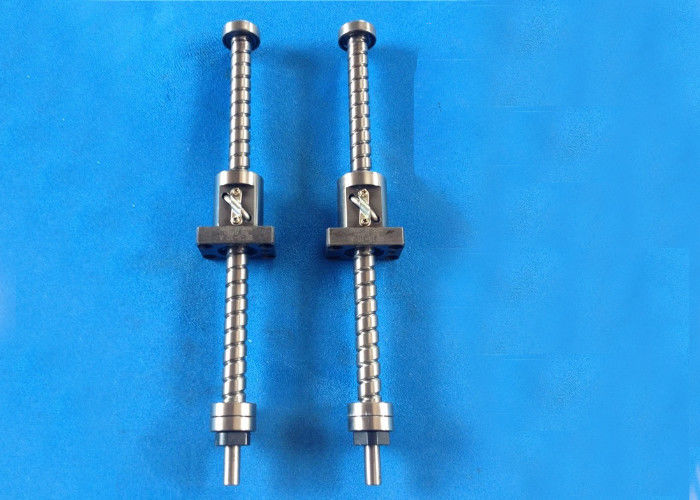

Ball screw, high load, high speed, precise positioning

-

Highlight

high speed Ball screw

,high load Ball screw

,precise positioning Ball screw

-

Product NameBall Screw

-

DesignModern

-

Material ScienceMetal

-

ColourSilvery

-

Place of OriginJapan

-

CertificationISO9001

-

Model NumberAll models

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom wrapping

Ball screw, high load, high speed, precise positioning

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

The ball screw occupies an important position in the fields of tool machinery and precision machinery. As a commonly used transmission component, it is widely used in many industrial equipment and precision instruments. The ball screw is carefully composed of various components such as screw, nut, and ball. Its outstanding function lies in being able to cleverly convert rotational motion into linear motion, providing strong guarantee for the accurate motion control of equipment. At the same time, there are many standardized products available on the market to meet the needs of different equipment. Moreover, it also has different circulation methods and preloading methods, and users can flexibly select according to specific application scenarios to achieve the best transmission effect and performance.

Technical Parameters:

F series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

|

High cycle speed, low noise, compact, long lifespan |

F series | FG series | Single Nut | C5 | Φ10~Φ25 | Unprocessed products at the end of the shaft |

| FE series | C7 | |||||

| FR series | Single Nut | C3~C7 | Φ10~Φ40 | Free design | ||

| Double nut | C3~C5 | Φ32~Φ40 | ||||

D Series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

| Compact, small feed positioning | D series | DP series | Single Nut | C3 | Φ6~Φ14 | Single end finished product |

| DR series | Single Nut | C0~C7 | Φ6~Φ50 | Free design | ||

| Integral Nut | C0~C5 | Φ16~Φ50 | ||||

H Series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

| High speed handling, high lead | H series | HG series | Single Nut | C5 | Φ8~Φ32 | Unprocessed products at the end of the shaft |

G Series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

| Multiple shaft diameters, multiple leads, positioning purposes, transportation purposes | G series | GP series | Single Nut | C3 | Φ8~Φ20 | Single end finished product |

| GG series | C5 | |||||

| GE series | C7 | Φ8~Φ32 | Unprocessed products at the end of the shaft |

|||

| GR series | Single Nut | C0~C7 | Φ5~Φ125 | Free design | ||

| Integral Nut | C0~C5 | Φ20~Φ63 | ||||

| Double nut | C0~C5 | Φ8~Φ125 | ||||

Cold rolled G series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

| Transportation purposes, various nut shapes such as circular, protruding, and square | Cold rolled G series | GW series | Single Nut | C5 | Φ8~Φ32 | Unprocessed products at the end of the shaft |

| GY series | C10 | Φ8~Φ40 | ||||

R Series

| Characteristics, keywords | series | Nut combination method | Accuracy level | Shaft diameter | The shape of the screw shaft | |

| Handling use, light load use | R series | RW series | Single Nut | C7 | Φ8~Φ32 | Unprocessed products at the end of the shaft |

Applicable scenarios:

Ball screws are widely used in various important fields. In machine tools, it ensures that cutting tools or workpieces can achieve precise linear motion control, thereby processing high-precision parts. In automated production lines, ball screws provide stable linear transmission for the efficient operation of equipment, improving production efficiency and product quality. In terms of precision measuring equipment, its high-precision linear motion control ability ensures the accuracy and reliability of measurement. In short, ball screws play a crucial role in these industrial equipment and precision instruments, providing strong support for the development of modern industry and the progress of science and technology.

Product Function:

Efficient transmission: The main function is to convert rotational motion into linear motion or torque into axial repeated force. It has high precision, reversibility, and high efficiency. Due to its small frictional resistance, it can achieve efficient power transmission in various equipment.

Component composition and function: Composed of screw, nut, steel ball, preload plate, reverser, and dust collector. Transforming the bearing from sliding motion to rolling motion greatly improves the precision and efficiency of movement.

Standardized products: Provide a wide range of standardized products to adapt to various application scenarios.

Multiple circulation methods: Widely used in machine tools. The circulation methods of balls include circulation conduit type, circulation device type, and end cover type to meet different usage needs.

Diverse preloading methods: The preloading methods include positioning preloading (double nut method, positioning preloading method) and fixed pressure preloading. It can be selected according to specific application requirements to ensure the performance and precision of the ball screw.

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

Ball screw is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()