30MM Thickness Ultra-high Rigidity SRW Linear Guide Rail with Strong Load Capacity and Biserial Rolling Element Columns

-

Highlight

30MM Thickness Linear Guide Rail

,Strong Load Capacity Linear Guide Rail

-

Thickness (mm)30MM

-

Number Of Rolling Element ColumnsBiserial

-

Material Of Rolling Bearing SeatBearing Steel

-

Place of OriginJapan

-

Model NumberSRW

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom packaging

30MM Thickness Ultra-high Rigidity SRW Linear Guide Rail with Strong Load Capacity and Biserial Rolling Element Columns

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

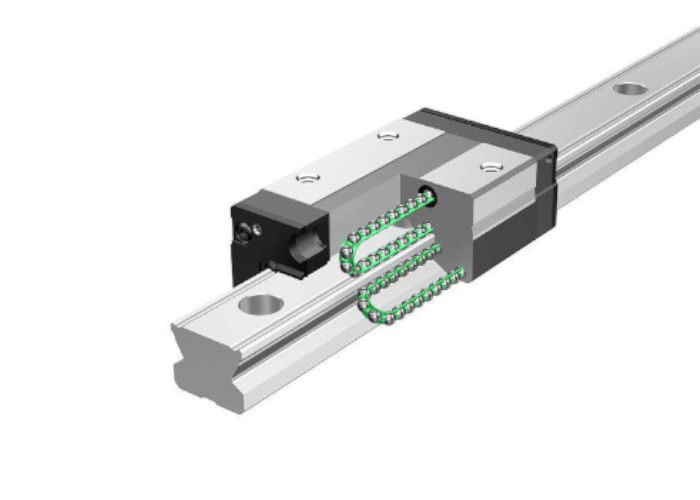

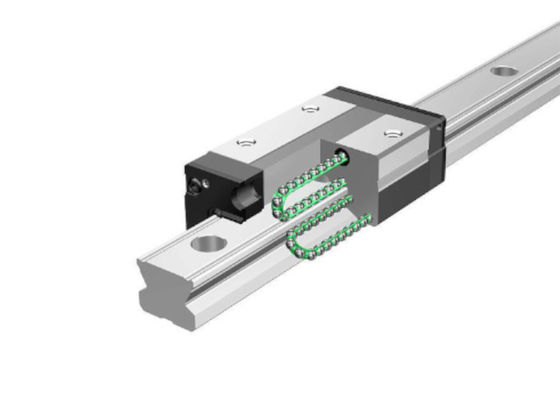

The SRW series linear guide stands out among numerous linear guide products with its unique design and excellent performance. This model widens the track width and is fixed by two rows of assembly bolts, significantly improving the installation strength. At the same time, it has a strong load-bearing capacity for moment loads in the rolling direction. Based on the cage-type roller rolling guide SRG type, it further optimizes the track amplitude and installation hole settings, combining high installation strength, stability, and the characteristic of smooth motion with low friction. It is an ultra-high rigidity roller guide that can operate for a long time without maintenance.

Technical Parameter:

| Model | External dimensions | LM slider size | |||||||

| Height M | Width W | Length L | B | C | L1 | T | K | N | |

| SRW 70LR | 70 | 135 | 190 | 115 | 80 | 142 | 20 | 62 | 20 |

| SRW 85LR | 80 | 165 | 235 | 140 | 95 | 179.2 | 28 | 70 | 22 |

| SRW 100LR | 100 | 200 | 303 | 172 | 110 | 229.8 | 20 | 88.5 | 27 |

| SRW 130LR | 130 | 260 | 350 | 220 | 140 | 250.8 | 30 | 114 | 25 |

| SRW 150LR | 150 | 300 | 395 | 260 | 200 | 280.2 | 35 | 134 | 28.8 |

![]()

Applicable scenarios:

The SRW series linear guides are suitable for various fields that have high requirements for installation strength, rigidity, smooth motion, and maintenance-free operation, such as precision machining equipment, automated production lines, and heavy industrial equipment. In these fields, the SRW series linear guides can provide reliable guarantees for the efficient operation and long-term stable work of equipment.

Product Function:

Ultra-high rigidity:

The widened track width and the design of being fixed by two rows of assembly bolts significantly enhance the installation strength. The large lateral rolling surface distance (L) endows it with strong load-bearing capacity for moment loads (Mc moment) in the rolling direction.

Using rollers with low elastic deformation as rolling elements and having a total roller length greater than 1.5 times the roller diameter further improves rigidity.

Achieving smooth motion by preventing offset:

Using roller retainers to evenly separate and arrange the rollers for circulation effectively prevents roller displacement when the slider reaches the load area and minimizes the fluctuation of rolling resistance, realizing smooth and stable motion.

Long-term maintenance-free operation:

The roller retainers eliminate mutual friction between rollers and keep grease in the grease pockets between adjacent rollers. During the roller circulation process, the grease pockets can provide the necessary amount of grease for the contact surface between the isolation plate and the rollers, ensuring long-term maintenance-free operation.

SRW type lubrication hole:

The SRW type allows lubrication from both the side and top surfaces of the linear guide slider. To prevent foreign objects from entering the linear guide slider, the standard component does not have a drilled-through lubrication hole. If there is a need to use lubrication holes, consult [relevant source].

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

Ultra-high rigidity type (wide width type) SRW linear guide rail is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()