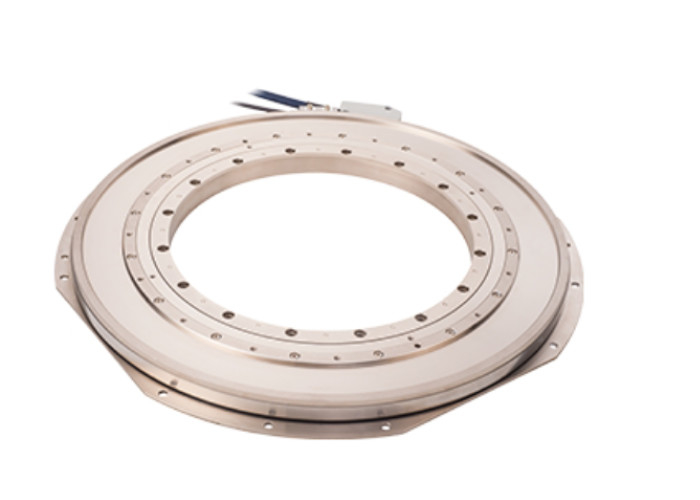

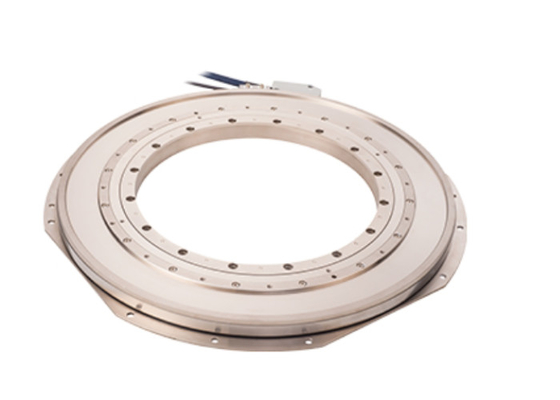

Continuous Current 3.5 Arms Linear Servo Motor Hollow Shaft Diameter Ø140 mm Ø340 mm

-

Highlight

Continuous Current Linear Servo Motor

,3.5 Arms Linear Servo Motor

,Hollow Shaft Linear Servo Motor

-

Hollow Shaft DiameterØ140 Mm - Ø340 Mm

-

Thickness22 Mm-30 Mm(

-

Continuous Torque1.26 Nm

-

Continuous Current3.5 Arms

-

Torque Constant0.35 Nm/A Rms

-

Thermal Resistance0.65 ℃/W

-

Place of OriginTaiwan

-

Model Numberthin direct drive motor

-

Minimum Order QuantityNegotiate

-

PriceNegotiate

-

Packaging DetailsCustom packaging

Continuous Current 3.5 Arms Linear Servo Motor Hollow Shaft Diameter Ø140 mm Ø340 mm

The pictures, models, parameters and other relevant information displayed in the product are for reference only. If you are searching for products related to fields such as electronic components, precision components, office automation, and factory automation, or if you need customized products in this field. Welcome to contact us through the consultation form, telephone or any way you find convenient. We will reply to you as soon as possible. We always adhere to the purpose of striving for the best to provide you with the highest quality service. We look forward to establishing a friendly and stable cooperative relationship with you.

Product Description:

The direct drive motors play an important role in the fields of semiconductors, precision manufacturing, and automation equipment due to their excellent technical performance and wide application range. Its high-precision positioning, high-speed response, energy-saving and environmental protection, and high rigidity design provide users with efficient, stable, and reliable driving solutions. Meanwhile, customized services also provide strong support to meet the special needs of different customers.

Technical Parameter:

| Model | Unit symbol | B2 | F2 | K3 |

| Motor wattage | W | 334 | 438 | 487 |

| Continuous torque | Nm | 9.1 | 19 | 31 |

| Continuous current | Arms | 2.6 | 2.6 | 2.6 |

| Instantaneous torque (1s) | Nm | 30.4 | 63.6 | 110 |

| Instantaneous current (1s) | Arms | 8.7 | 8.7 | 8.7 |

| Torque constant | Nm/Arms | 3.5 | 7.3 | 13.5 |

| time constant | ms | 0.7 | ||

| Inter line resistance (coil temperature 25C) | Ω | 11.7 | 17.2 | 23.8 |

| Inter line inductance | mH | 8.6 | 12.3 | 16.7 |

| Extreme numbers | - | 32 | 48 | 60 |

| Reverse electromotive force (line to line) | Vrms/(rad/s) | 2 | 4.2 | 7.8 |

| Motor constant (coil temperature 25C) | Nm/√W | 0.8 | 1.4 | 2.3 |

| thermal resistance | K/W | 0.63 | 0.43 | 0.33 |

| Temperature sensor | - | PTC100 | ||

| Maximum operating voltage | VDC | 500(600) | ||

| Rotor moment of inertia | kgm2 | 0.04 | 0.13 | 0.4 |

| Motor quality | kg | 6.5 | 9.3 | 0.4 |

| Maximum axial load | N | 500 | 750 | 750 |

| Maximum torque load | Nm | 50 | 75 | 75 |

| Maximum speed | rpm | 350 | 220 | 100 |

| resolving power | p/rev | 3686400 | 4319232 | 4324800 |

| Reproduce accuracy | arc-sec | ±2 | ±1.5 | ±1.5 |

| accuracy | arc-arc-sec | ±20/±10/±5 | ±15/±10/±5 | ±15/±10/±5 |

| Axial deflection | mm | 0.03 | 0.01 | |

| Radial deflection | mm | 0.03 | 0.01 | |

| height | mm | 22 | 22 | 30 |

| Hollow diameter | mm | 140 | 240 | 340 |

Applicable scenarios:

Double sided detection: With its large hollow design and high-precision positioning capability, direct drive motors are widely used in product double-sided detection systems to improve detection efficiency and accuracy.

Backlight module manufacturing: In the production line of backlight modules, the can save space, reduce equipment center of gravity, and enhance equipment rigidity, thereby improving production efficiency and product quality.

Precision positioning platform: As the core component of the XY θ positioning platform, the direct drive motor can achieve low center of gravity and high rigidity precision positioning, meeting the requirements of high-precision machining and inspection.

Product Function:

High precision positioning: The direct drive motor achieves micrometer level or even sub micrometer level positioning accuracy through a precise control system and advanced motor technology, meeting the requirements of high-precision machining and testing.

High speed response: With low inertia design and optimized dynamic performance, the can quickly respond to control commands in a short period of time, achieving high-speed and stable motion control.

Energy saving and environmental protection: Adopting advanced motor materials and drive technology, the direct drive motor not only improves performance, but also effectively reduces energy consumption and noise, in line with the concept of green manufacturing.

High rigidity design: By optimizing structural design and material selection, direct drive motors not only enhance rigidity but also ensure structural stability and durability, ensuring long-term reliability.

Customized service: Provide customized direct drive motor solutions tailored to the application needs of different customers, including personalized customization of size, performance parameters, and additional functions.

Support and Services

- 24/7 customer service support to answer any questions.

- Expert advice on product selection and troubleshooting.

- Detailed product information and training materials.

- Full warranty and repair services.

- Product updates and upgrades.

Packing and Shipping

Thin direct drive motor is packaged and shipped in a cardboard box that is designed to keep the product safe and secure during transit. The box has a custom-sized insert to fit the product securely, and is sealed with tape. Inside the box, the product is wrapped in bubble wrap and foam padding to provide additional cushioning and protection. A packing slip and any promotional materials are included in the package.The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

The package is then shipped via a reliable carrier such as UPS or FedEx. Tracking information is provided to the customer to follow the package's progress. Delivery time will vary depending on the chosen shipping method and destination.

![]()